10 Simple Techniques For Motorcycle Parts New Zealand Specialists

Table of ContentsSee This Report on Motorcycle Parts New Zealand SpecialistsMore About Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?The Main Principles Of Motorcycle Parts New Zealand Specialists How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.More About Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand Specialists

Reach out to one of our specialists today.CNC machining innovation is swiftly ending up being the centerpiece of several production procedures around the world as a direct outcome of its lots of advantages over various other approaches. In addition, the markets that manufacture bikes have jumped on board with this fad. One of the most cutting-edge firms are now creating their engine components and wheels making use of machining techniques originally created for motorbike parts.

You might be wondering why we utilize. Now that we have your focus let us discuss the reasoning behind this contemporary advancement in the motorbike production market.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

In addition, you have complete control over the look of the elements, also down to the minute information. Occasionally, motorcyclists might make a decision to spruce up their adventure by mounting aftermarket components or modifying the bike's remodeling.

The Main Principles Of Motorcycle Parts New Zealand Specialists

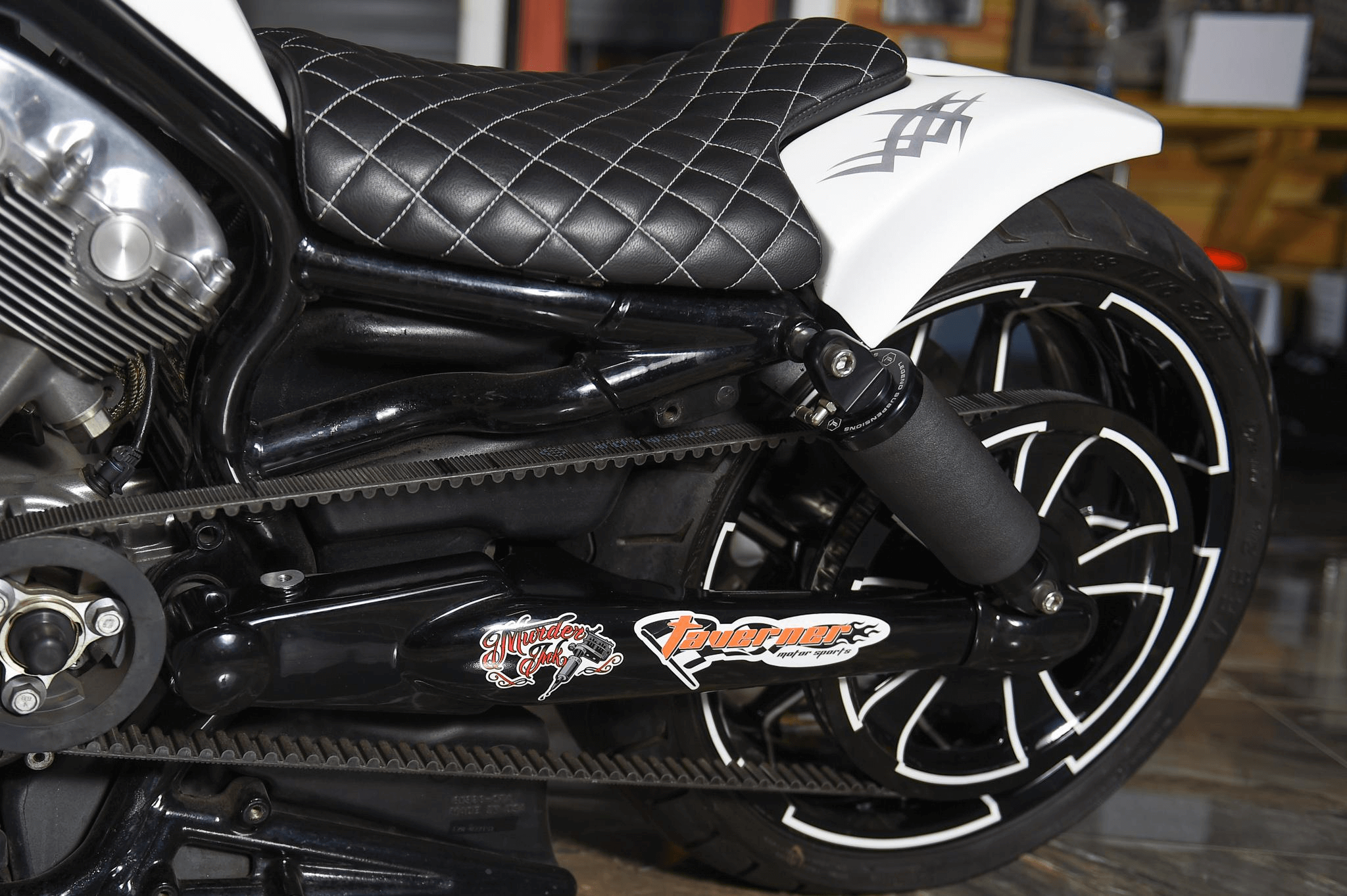

CNC machining might be made use of to make nearly all of a motorcycle's steel and plastic components. To continue, we'll discuss a number of machined components for bikes. Unlike those on cars and trucks, wheels on motorcycles often tend to be more evident. Therefore, the bike's looks may be boosted with the appropriate personalization of these wheels.

Milling procedures are utilized to acquire the preferred level of wheel customization. Another facet of the bike that may be customized is the tires.

6 Simple Techniques For Motorcycle Parts New Zealand Specialists

When it involves a car (or a motorbike), one of the most crucial element is the engine. Numerous individuals point to it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be intricate and call for designs with a high level of precision.

Illumination is one more complicated aspect of modification. Use just premium things, nonetheless, given that these lights are essential for the safety and security of motorcyclists and other chauffeurs or people when traveling, especially in the evening. Motorcycle headlights have 3 almosts all: the bulb, or light resource, the lens, and the real estate. Specifically, we tailor the lens and the housing.

Milling processes with a perfect surface would cause the lenses having a reflective quality that is similar to that of a mirror. The cover, on the various other hand, is not composed of vulnerable products; instead, it is built out of challenging polymers that can be machined right into even more complex patterns.

Some Ideas on Motorcycle Parts New Zealand Specialists You Should Know

Bike producers often cast these parts, but just for the production of bespoke components. Machining on 5 axes in today's world is the methods by which any style shape may be realized.

Select Runsom for your customized motorcycle parts! We have the capacity to make difficult and fashionable components making your motorbike unparalleled.

Below are a couple of instances of metals typically utilized in bike element machining. Aluminum is the main product great site made use of by business concentrating on creating customized motorbike parts to create the majority of these parts. In the past, we would develop our engines out of cast iron. On the other hand, light weight aluminum is rapidly ending up being the material of option, partly because of the fact that it is much more lightweight.

Zinc refers to another metal that is very light in weight and has great machining qualities due to its high mechanical toughness. This material may be developed useful content into virtually any kind of shape and preserves its dimensions well. Also mission-critical parts that require a high degree of accuracy may take advantage of their usage.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

An additional steel that sees heavy use in the production of CNC-customized components is magnesium. It is amongst the lightest steels look at more info that are currently accessible and has exceptional machinability functions and stamina commensurate with its low weight. One of the drawbacks of magnesium is that its dust might easily ignite.

As a result of its exceptional machinability and weldability, stainless-steel is an alloy that is particularly appropriate for CNC procedures. They have great corrosion resistance and a high aesthetic allure. Their most usual usage in creating different motorbike parts is bolts, such as screws and screws. Their low vulnerability to oxidation and rust makes them perfect for this use.

The Motorcycle Parts New Zealand Specialists Ideas

It appears that CNC transforming and crushing are the fundamental processes. In addition, it requires keeping bars of product, most usually plastic or steel, in setting and after that twisting a cutting device to remove areas of the product as the product is turned.

These approaches are similarly essential and create elements with high precision and constant high quality. The procedures assist enhance the general quality of the machined motorcycle parts.

Motorcycle Parts New Zealand Specialists for Dummies